What Is Asset Inspection?

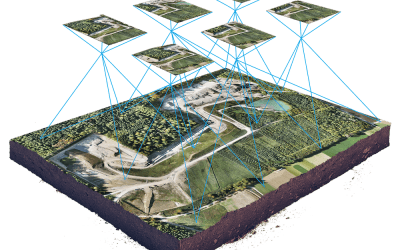

Asset Inspection is the task of surveying or assessing the physical condition of an asset, to create data that can be used in the efficient and effective management (governance) of that asset over its life-cycle. Asset inspection is a process of evaluating and examining physical assets to assess their condition, performance, and compliance with standards or regulations. These assets can include machinery, equipment, infrastructure, buildings, vehicles, or any other tangible property owned or utilized by an individual, organization, or government entity.

The purpose of asset inspection can vary depending on the context. It may involve routine maintenance checks to ensure assets are functioning properly and to identify any potential issues before they escalate into costly problems. Asset inspection can also be conducted for regulatory compliance purposes, such as ensuring that equipment meets safety standards or environmental regulations. Asset inspections are typically carried out by trained inspectors or technicians who use various tools and techniques to conduct thorough examinations. These may include visual inspections, measurements, testing, and documentation of findings. Inspection reports are often generated to summarize the condition of the assets and any recommended actions, such as repairs or replacements.

How to Verify Asset

Verifying assets for inspection involves several steps to ensure that the inspection process is thorough and effective.

Identify Assets: Begin by compiling a comprehensive list of all the assets that require inspection. This list should include details such as the asset type, location, serial number (if applicable), and any relevant documentation or maintenance records.

Determine Inspection Criteria: Establish clear criteria for the inspection based on factors such as the type of asset, its criticality, industry regulations, and maintenance requirements. This will help guide the inspection process and ensure that all relevant aspects of the asset are examined.

Schedule Inspections: Develop a schedule for conducting inspections based on factors such as asset criticality, usage frequency, and maintenance schedules. Ensure that inspections are planned in advance and coordinated with relevant personnel to minimize disruption to operations.

Assign Responsibilities: Assign specific roles and responsibilities to individuals or teams responsible for conducting inspections. This may include trained inspectors, technicians, maintenance personnel, or third-party service providers.

Gather Inspection Tools and Equipment: Ensure that inspectors have access to the necessary tools, equipment, and resources needed to conduct thorough inspections. This may include measurement devices, testing equipment, safety gear, inspection checklists, and documentation materials.

Perform Pre-Inspection Checks: Before conducting inspections, perform pre-inspection checks to verify that assets are accessible, safe to inspect, and properly prepared. This may involve tasks such as shutting down equipment, securing work areas, and obtaining necessary permits or clearances.

Conduct Inspections: Follow the established inspection criteria and procedures to thoroughly examine each asset. Inspectors should visually inspect assets, perform measurements and tests as needed, and document any findings or observations.

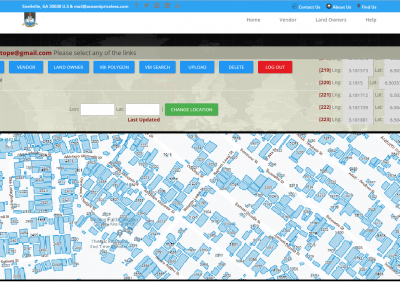

Document Inspection Results: Record inspection findings, including any defects, deficiencies, or areas of concern identified during the inspection. Use standardized forms or digital tools to document inspection results accurately and comprehensively.

Analyze Inspection Data: Analyze inspection data to identify trends, patterns, or recurring issues across assets. Use this information to prioritize maintenance activities, address underlying problems, and improve asset performance and reliability.

Implement Corrective Actions: Develop and implement corrective actions to address any issues or deficiencies identified during the inspection process. This may involve performing repairs, conducting maintenance tasks, or replacing assets as necessary.

By following these steps to verify assets for inspection, organizations can ensure that assets are thoroughly examined, maintained, and managed effectively to support operational efficiency, regulatory compliance, and asset performance goals.

What is an asset inspection report?

An asset inspection report is a formal document that summarizes the findings, observations, and recommendations resulting from an asset inspection. It provides a detailed overview of the condition, performance, and compliance status of inspected assets, along with any actions required to address identified issues.

Key components of an asset inspection report typically include:

Asset Information: This section provides basic details about the inspected assets, such as asset type, location, identification number, and relevant specifications.

Inspection Summary: A summary of the inspection process, including the date and time of the inspection, the names of inspectors or inspection team members, and any relevant contextual information.

Inspection Findings: Detailed descriptions of the findings and observations made during the inspection. This may include information about the condition of assets, any defects or deficiencies identified, and observations related to asset performance or compliance.

Recommendations: Suggestions for actions or measures to address the findings and improve the condition, performance, or compliance of the inspected assets. Recommendations may include repairs, maintenance tasks, replacements, or other corrective actions.

Supporting Documentation: Any supporting documentation, such as photographs, measurements, test results, or reference materials used during the inspection, may be included to provide additional context or evidence.

Conclusion: A concluding section that summarizes the key findings and recommendations of the inspection report and may provide additional commentary or insights.

Signature and Date: The inspection report typically includes spaces for signatures of inspectors or authorized personnel to certify the accuracy and completeness of the report. The date of the inspection and the date of the report’s preparation are also usually included.

Asset inspection reports serve as important records for documenting the condition and maintenance history of assets, supporting decision-making processes, and ensuring accountability for asset management and maintenance activities. They are often used by asset owners, maintenance teams, regulatory agencies, and other stakeholders involved in managing and overseeing assets.