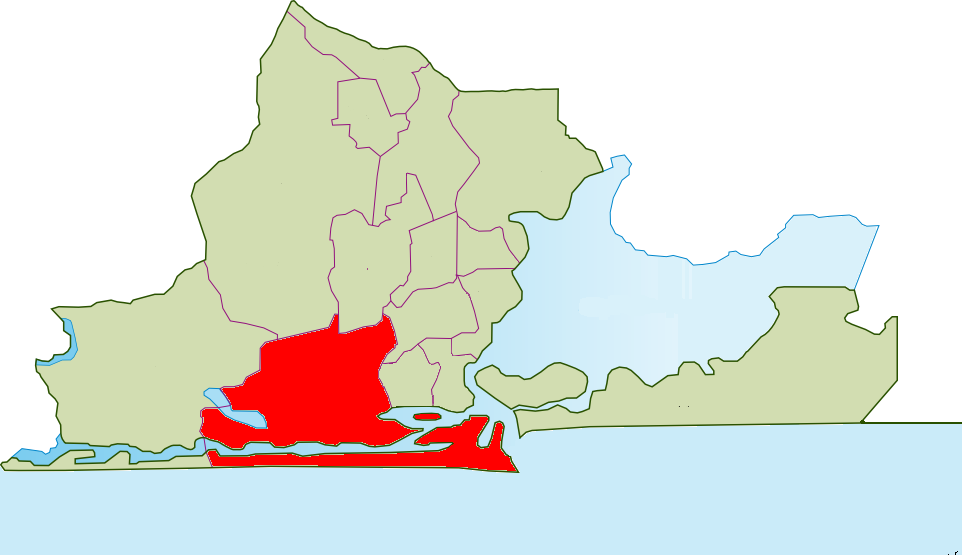

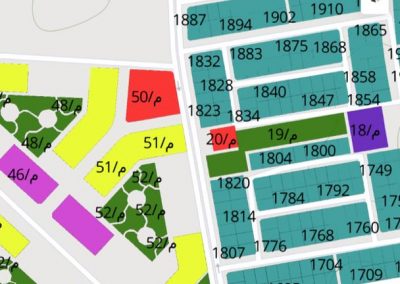

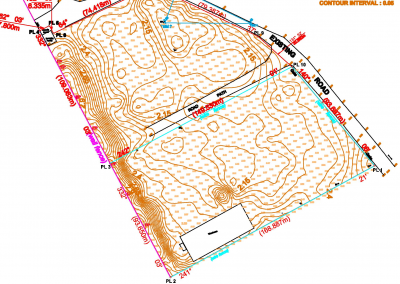

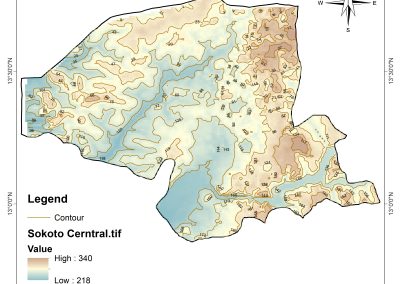

In the high-stakes world of Nigerian construction and real estate, accuracy is your currency. Whether you are mapping a new estate in Lekki or laying foundations in Kano, a single millimeter of error can lead to a multi-million Naira lawsuit.

However, between the Sahara-born Harmattan dust and the relentless 90% humidity of the Niger Delta, your expensive Total Stations and GNSS receivers are under constant attack. If you want to avoid costly project delays and keep your ISO compliance intact, this guide is for you.

1. Why Nigeria’s Climate is Tough on Survey Tools

Nigeria’s weather patterns aren’t just uncomfortable for people; they are “instrument killers.”

Sensor Drift: Extreme heat (reaching 40°C+) causes metal components to expand, throwing off internal precision.

Lichen & Fungus: In coastal cities like Lagos and Port Harcourt, moisture trapped in lenses leads to “clouding” that can permanently ruin expensive optics.

Electronic Corrosion: Salt-heavy humidity acts as an accelerant for rust on battery terminals and internal circuitry.

2. Daily Maintenance: The “No-Dust” Rule

In the North and during the Harmattan season in the South, silica dust is your #1 enemy. These microscopic particles can act like sandpaper on your horizontal and vertical circles.

The Microfiber Secret: Never use a rough rag or your shirt. Use a soft anti-static brush to whisk away dust before gently wiping with a specialized microfiber cloth.

The “Dry-Off” Routine: Surveying during the rainy season? Never put a damp instrument back in its case. This creates a “sauna effect” that breeds fungus. Wipe it down and let it air-dry in a cool, ventilated room first.

3. Master the Field Calibration (The Fortnightly Check)

You don’t always need a service center for basic checks. Given Nigeria’s bumpy road conditions (which can shift internal compensators), perform a Two-Peg Test for levels every two weeks.

Pro Tip: Before every high-accuracy project, run the internal electronic calibration software on your Total Station to account for atmospheric pressure and temperature changes.

4. Storage: Beating the Lagos Humidity

Silica Gel Packs: Always keep fresh, color-indicating desiccant (silica gel) inside your equipment cases. When it turns pink, it’s time to dry it out or replace it.

Battery Care: Heat kills lithium-ion batteries. Never leave your GNSS rover or Total Station batteries in the boot of a car parked under the Nigerian sun. Store them in a cool, shaded area.

5. Professional Calibration Services in Nigeria

While DIY checks are great for daily work, an annual professional calibration is non-negotiable for Tier-1 contractors like Julius Berger or Dangote. In 2026, you won’t even be allowed on-site without a valid Calibration Certificate.

Where to Calibrate?

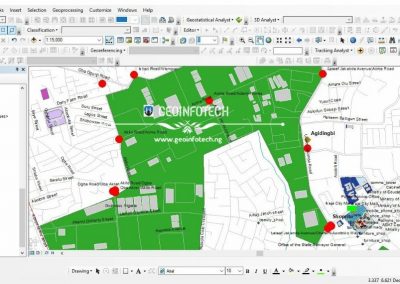

Lagos: Visit certified centers in Ikeja (Alausa) or Victoria Island (e.g., Geoinfotech).

Port Harcourt: Specialized labs in the Trans-Amadi area serve the oil & gas industry.

Abuja: Government-approved centers for federal projects are located within the CBD.

Summary Checklist for the Nigerian Surveyor

| Task | Frequency | Why? |

| Dust Brushing | Every Use | Prevents mechanical jams and “sandpaper” wear. |

| Battery Removal | Every Night | Prevents terminal corrosion and internal leaks. |

| Field Check (Peg Test) | Every 2 Weeks | Corrects errors caused by road vibrations. |

| Pro Calibration | Annually | Ensures legal & technical accuracy for C of O work. |