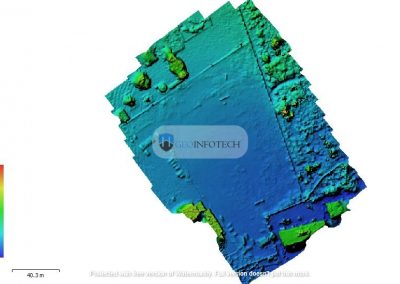

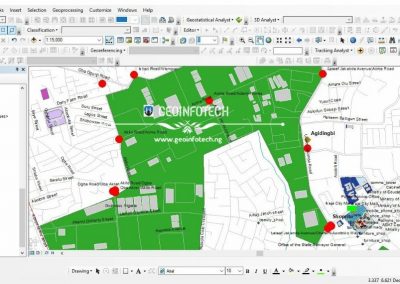

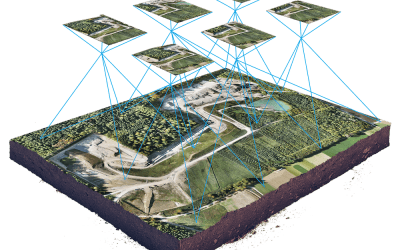

Drones have become indispensable tools across industries, from capturing aerial imagery for GIS mapping to monitoring crops in precision agriculture and inspecting hard-to-reach infrastructure. But like any high-tech equipment, drones require regular care to perform at their best. Without proper maintenance, you risk costly repairs, inaccurate data, or even crashes that could halt your projects. This ultimate guide dives into the essentials of drone health and maintenance, offering expert tips to keep your fleet soaring and delivering reliable results for remote sensing, GIS, and beyond.

Why Drone Maintenance Is a Game-Changer

Drones are complex systems, combining advanced sensors, cameras, and flight hardware to deliver critical data. Neglecting maintenance can lead to serious setbacks:

- Costly Downtime: A single damaged component, like a worn propeller, can ground your drone, delaying projects and frustrating clients.

- Compromised Data: Dirty or miscalibrated sensors can produce unreliable imagery, undermining GIS analyses or remote sensing applications.

- Safety Risks: Faulty drones increase the chance of accidents, potentially violating aviation regulations like those set by the FAA.

- Reduced Lifespan: Skipping routine care can shorten your drone’s operational life, forcing expensive replacements sooner than expected.

Proactive maintenance ensures your drones stay reliable, safe, and cost-effective, maximizing their value for your operations. Let’s explore the key components to monitor and how to keep them in top condition.

Critical Drone Components to Inspect

To keep your drones performing at their peak, regularly check these essential components:

1. Propellers

Propellers are critical for stable flight and safety. Even minor damage can cause vibrations that affect data quality or lead to crashes.

- What to Check: Inspect for cracks, chips, or bends. Worn propellers reduce lift and strain motors.

- Maintenance Tip: Check propellers before and after every flight. Replace any showing signs of wear, and keep a stock of spares for quick swaps.

2. Batteries

Batteries power your drone’s flights, and poor care can drastically reduce their lifespan or cause mid-air failures.

- What to Check: Monitor charge cycles (typically 200–300 per battery), look for swelling or corrosion, and ensure connectors are clean.

- Maintenance Tip: Store batteries at 50–60% charge in a cool, dry environment (15–25°C). Avoid full discharges or storing them fully charged.

3. Sensors and Cameras

For remote sensing and GIS applications, sensors and cameras must deliver crisp, accurate data.

- What to Check: Inspect multispectral, thermal, or LiDAR sensors for dust, smudges, or misalignment. Check camera lenses for scratches.

- Maintenance Tip: Clean optics with a microfiber cloth and lens cleaner. Calibrate sensors every 50–100 flights or after heavy use to ensure data precision.

4. Motors and Frame

Motors and the drone’s frame endure significant stress during flights, especially in demanding environments.

- What to Check: Listen for unusual noises or vibrations, and inspect the frame for cracks, loose screws, or structural wear.

- Maintenance Tip: Clean motors with compressed air to remove debris. Tighten loose components and schedule professional motor servicing every 200 flight hours.

By keeping these components in check, you ensure your drones are ready for any mission, whether mapping a sprawling farm or inspecting a skyscraper.

Best Practices for Routine Drone Maintenance

A consistent maintenance routine is the key to long-term drone performance. Here’s how to make it part of your workflow:

Pre-Flight Checklist

- Inspect propellers, batteries, sensors, and the frame for visible issues.

- Verify firmware and software updates for the drone and any GIS integration tools.

- Calibrate the compass and IMU (Inertial Measurement Unit) in an open, interference-free area.

- Check weather conditions to avoid stress on components (e.g., high winds or extreme heat can strain motors).Post-Flight Checklist

- Clean sensors and lenses to remove dust, pollen, or smudges that could affect data quality.

- Log flight details (e.g., duration, battery usage) to track performance trends, ideally in a GIS platform for easy analysis.

- Store drones in a padded, climate-controlled case to protect against humidity or temperature fluctuations.

Regular Maintenance Schedule

- Weekly: Clean the drone body and sensors; check for loose parts or wear.

- Monthly: Update firmware, test battery health with a charger or diagnostic tool, and inspect motors for signs of wear.

- Quarterly: Consider professional servicing for in-depth diagnostics, especially for high-use drones in industries like agriculture or infrastructure.

Storage Best Practices

- Use padded cases to protect drones from physical damage.

- Store batteries separately at partial charge to prevent degradation.

- Keep drones in a dry, dust-free environment to safeguard electronics and sensors.

These habits ensure your drones are always mission-ready, whether you’re collecting data for urban planning or monitoring environmental changes.

Leveraging GIS for Smarter Drone Maintenance

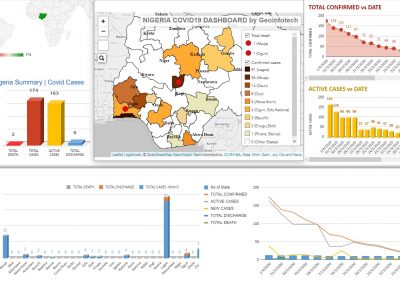

GIS isn’t just for mapping—it can revolutionize how you maintain your drone fleet. By integrating flight data into GIS platforms, you can:

- Track Performance Metrics: Log flight hours, battery cycles, and sensor performance to spot trends, like declining battery efficiency.

- Predict Maintenance Needs: Analyze data to anticipate issues, such as motor wear or sensor drift, before they cause failures.

- Optimize Operations: Use GIS to map flight patterns and identify high-stress missions (e.g., long flights over rugged terrain) that require extra maintenance.

For example, a precision agriculture company used GIS to track drone performance across 1,200 flights, identifying a sensor misalignment that was skewing crop health data. By recalibrating proactively, they improved data accuracy by 25%, saving thousands in potential rework. This data-driven approach keeps your drones reliable and your projects on track.

Common Drone Maintenance Mistakes to Avoid

Even seasoned operators can fall into traps that compromise drone health. Here’s what to watch out for:

- Skipping Firmware Updates: Outdated firmware can cause glitches or compatibility issues with GIS software, leading to data errors or flight instability.

- Ignoring Environmental Factors: Flying in rain, high winds, or extreme heat can damage motors, sensors, or batteries. Always check manufacturer-recommended conditions.

- Neglecting Battery Care: Storing batteries fully charged or fully depleted can cut their lifespan by up to 50%. Follow proper storage protocols to maximize longevity.

- Overlooking Sensor Calibration: Uncalibrated sensors can produce inaccurate remote sensing data, undermining GIS analyses for applications like environmental monitoring or urban planning.

Avoiding these mistakes ensures your drones perform reliably, delivering high-quality data every time.

Conclusion

Drones are powerful tools, but their performance hinges on proper care. By monitoring critical components, following a routine maintenance schedule, and leveraging GIS for data-driven insights, you can keep your fleet flying high and your projects on target. Whether you’re mapping forests, inspecting pipelines, or optimizing crop yields, a well-maintained drone is the key to success.

Ready to take your drone operations to the next level? Start implementing these maintenance tips today, and explore how GIS can streamline your workflow. For more insights on drones, remote sensing, and geospatial technology, stay tuned for our next post on harnessing drone data for smarter decision-making.