Introduction

Thermal imaging and inspection is a powerful non-contact and non-destructive technique used to visualize and measure the temperature distribution across the surface of an object or environment. It relies on detecting infrared (IR) radiation emitted by all objects above absolute zero temperature (−273.15°C). Unlike visible light cameras, thermal imaging cameras can “see” heat, allowing engineers, technicians, and researchers to detect anomalies, inefficiencies, or hidden problems that are not visible to the naked eye. This technology is widely used in engineering, agriculture, building diagnostics, electrical inspection, industrial maintenance, medical applications, environmental monitoring, and even military and security operations.

Principle of Thermal Imaging

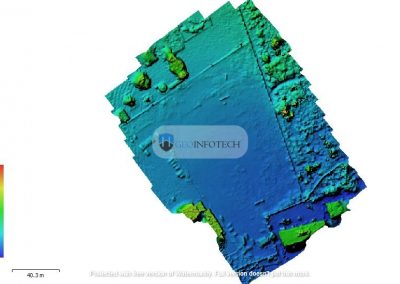

Every object emits infrared radiation proportional to its temperature. Thermal imaging sensors detect this IR energy and convert it into electronic signals, which are then processed to create a color-coded image known as a thermogram.

- Hotter areas appear in brighter or warmer colors (red, orange, yellow).

- Cooler areas appear in darker or cooler colors (blue, purple, black).

The intensity of infrared emission depends on:

- The surface temperature of the object.

- The emissivity of the material (how effectively it emits infrared energy).

- The ambient environment, including reflections and atmospheric conditions.

Components of a Thermal Imaging System

A typical thermal imaging system consists of the following components:

- Infrared Lens: Focuses the thermal radiation onto the detector.

- Infrared Detector (Sensor Array): Converts the thermal radiation into electrical signals. Common sensors include microbolometers (uncooled) and photon detectors (cooled).

- Signal Processing Unit: Converts raw data into temperature values and images.

- Display Unit: Shows the thermal image (thermogram) in real-time.

- Calibration and Analysis Software: Used for measurement, reporting, and analysis of temperature differences.

Types of Thermal Imaging Cameras

There are two types of thermal imaging camera which are stated as follows:

- Cooled Infrared Cameras: The characteristics of cameral include:

- Contain cryogenically cooled sensors (−200°C to −300°C).

- Provide high sensitivity and resolution.

- Used in scientific research, defense, and aerospace applications.

- Expensive and require maintenance.

- Uncooled Infrared Cameras:

- Operate at ambient temperatures using microbolometer arrays.

- Compact, affordable, and widely used in industrial and commercial inspections.

- Ideal for maintenance, building diagnostics, and drones.

Thermal Inspection Techniques

Thermal inspection involves analysing thermal patterns to identify irregularities that could indicate potential problems. The techniques include:

- Passive Thermal Inspection:

- The object naturally emits heat without external stimulation.

- Common in electrical, mechanical, and building applications.

- Active Thermal Inspection:

- External heat is applied (e.g., lamps, hot air) to stimulate thermal responses.

- Used for material testing, defect detection, and composite analysis.

Conclusion

Thermal Imaging and Inspection is a transformative tool that enhances safety, efficiency, and reliability across various sectors. By visualizing invisible heat patterns, it allows professionals to detect potential problems early, optimize system performance, and make informed decisions. As technology advances integrating drones, AI, and real-time analytics thermal imaging continues to evolve into a cornerstone of modern inspection and monitoring systems.