Introduction

Thermal imaging and inspection have become essential in nondestructive testing (NDT) for modern industries. This technology detects heat variations in equipment, structures, and environments without physical contact. By identifying abnormalities through infrared sensors, thermal inspection improves safety, reduces maintenance costs, and supports predictive monitoring in complex systems.

A. Industrial & Engineering Applications

- Electrical Systems: Thermal cameras detect loose connections, overloaded circuits, and overheating components before failure occurs.

- Mechanical Systems: Inspectors use infrared scans to monitor pumps, motors, and bearings for abnormal heat signatures.

- Predictive Maintenance: Technicians locate faults early, optimize maintenance schedules, and minimize equipment downtime.

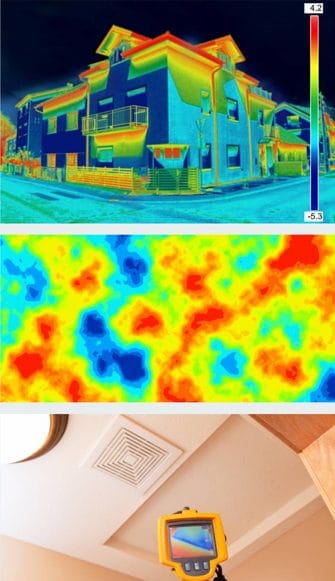

B. Building & Civil Infrastructure

- Insulation Assessment: Thermal inspection identifies heat loss, poor insulation, and moisture intrusion in buildings.

- Structural Monitoring: Thermal imaging visualizes damp zones and bridges in walls and slabs.

- Roof Surveys: Infrared cameras detect leaks beneath roofing surfaces and insulation layers.

C. Energy & Power Systems

- Solar System Diagnosis: Thermal inspection reveals defective solar cells and hotspots affecting power generation.

- Power Transmission: It detects faults in electrical insulators, connectors, and conductors.

- Transformers & Substations: Thermal scans show overheating that could lead to catastrophic failures.

D. Environmental & Agricultural Monitoring

- Precision Agriculture: Thermal cameras monitor crop stress, irrigation needs, and plant health.

- Wildlife Tracking: They help detect animals in low visibility conditions such as night or dense vegetation.

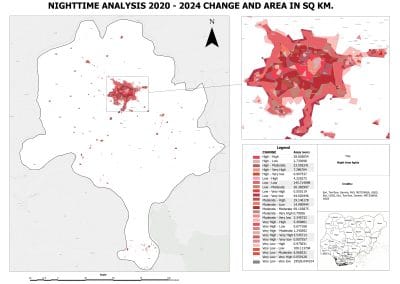

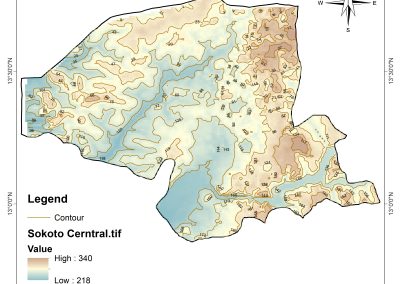

- Environmental Studies: Researchers map temperature variations in ocean surfaces, landfill sites, and ecosystems.

E. Medical & Veterinary Applications

- Medical Diagnosis: Thermal imaging identifies inflammation, circulatory issues, and infection indicators.

- Veterinary Monitoring: It detects injuries and abnormal temperature changes in animals without physical contact.

F. Security & Surveillance

- Night Vision: Security teams detect intruders in darkness, fog, or smoke.

- Border & Law Enforcement:Thermal systems monitor hidden threats, illegal crossings, and concealed objects.

- Firefighting: Firefighters locate victims in smoke-filled areas and pinpoint fire sources quickly.

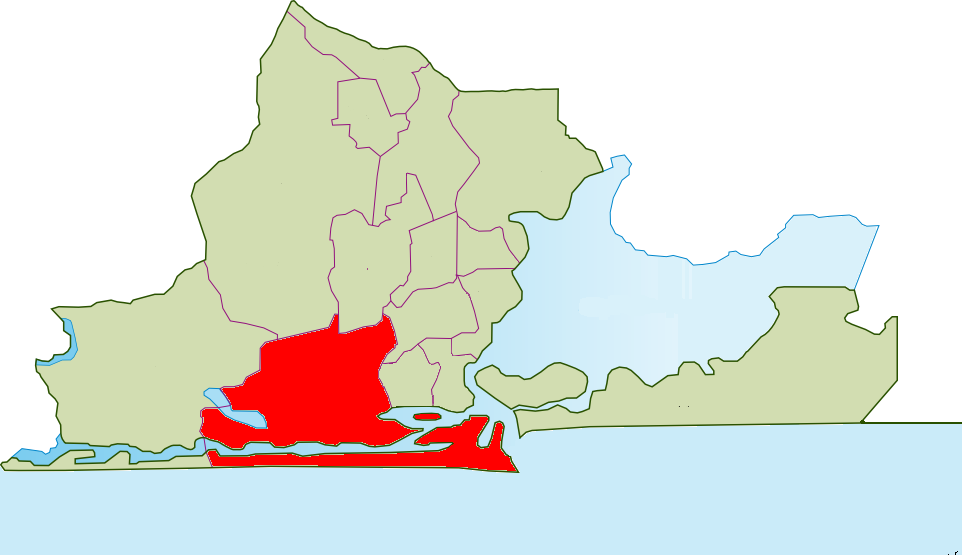

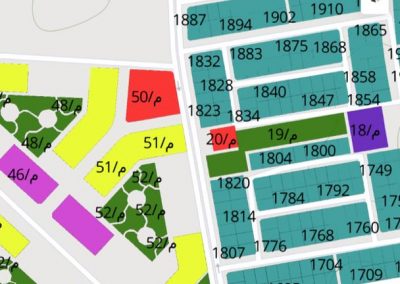

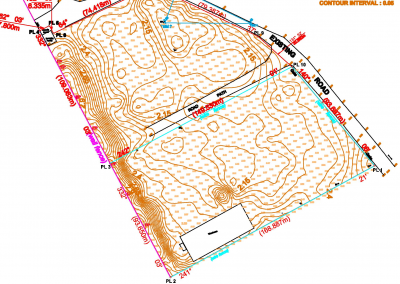

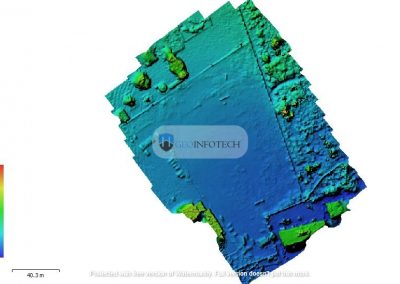

Figure 1: Drone Environmental Thermal Imaging for Solid Waste Landfill

Advantages of Thermal Imaging

Safe, non-contact inspection

Works in total darkness, fog, or smoke

Detects hidden faults invisible to the eye

Enables early problem detection

Reduces maintenance costs and downtime

Provides real-time results and documentation

Limitations of Thermal Imaging

Cannot see through walls or glass

Accuracy depends on emissivity

Affected by sunlight, wind, and surface condition

Expensive high-quality devices

Requires trained professionals

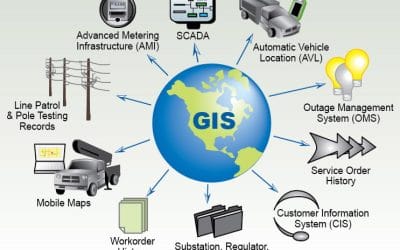

Integration with Modern Technologies

- Drones (UAVs): Used for aerial inspections of power lines, buildings, landfills, and farms.

- AI & Machine Learning: Automates anomaly detection and fault classification.

- IoT Sensors: Enables remote, real-time monitoring of industrial systems.

- 3D Thermal Mapping: Combines photogrammetry and infrared thermal data for detailed 3D analysis.

Conclusion

Thermal imaging and inspection play a vital role in safety, maintenance, and environmental monitoring. By combining infrared technology with AI, drones, and IoT, industries can prevent failures, reduce costs, and improve operational efficiency. This powerful technology continues to expand across global sectors, making it an essential tool for predictive and intelligent monitoring systems.